From Discovery to Scale-Up

Flexible Work Packages for Enzyme Development

Any Stage | Any Scale | Standard or Customised.

Flexible Entry Points – Start Anywhere

Customers can engage at any stage of their journey. Just tap into one or more of the modules, from early enzyme discovery and engineering to microbial expression, production strain development, bioprocess development and full-scale commercial manufacturing.

End-to-End Integration – One Partner with the end in mind

Seamlessly link enzyme development, bioprocess development, and manufacturing. Reduces technical transfer risks, project delays, and costs compared to working with multiple providers.

Advanced Toolbox – Innovative Tools for the Best Solution

Dedicated expert teams continuously implement the latest technologies (e.g. AI tools, bioinformatics) and even push the boundaries in developing proprietary technologies (e.g. MetXtra™, CRISPR-BMC, Plug & Produce) to give our customers competitive advantage.

Proven Scalability – Lab to 10,000L

Expertise and infrastructure to ensure smooth scale-up with reproducible yields and consistent quality. De-risks the transition from R&D to commercial production.

Speed to Market – Shorter Development Cycles

Experienced experts from various fields of enzyme development use state-of-the-art technologies to speed up progress and clearly defined milestones to accelerate decision-making and cut months off typical timelines.

Transparent IP & Freedom to Operate

Clear, customer-friendly IP model with no hidden licensing traps. Enables long-term security and commercial freedom for customers’ innovations.

Enzyme Scale-up & Manufacturing Services

Plug & Produce (basic): Escherichia coli: Rapid plasmid-based expression (AMR or AMR-free). Bacillus subtilis: Chromosomal integration (AMR-free) with evaluation of up to 2 constructs (e.g. signal peptide or gene design variations). Komagataella phaffii (Pichia pastoris): Evaluation of up to 2 constructs using different promoters (methanol or methanol-free induction), signal peptides, or gene designs chromosomally integrated (AMR-free).

Plug & Produce (extensive): Bacillus subtilis: Chromosomal integration (AMR-free) with evaluation of up to 6 constructs with variations in signal peptides, codon optimization, or strain genotypes. Komagataella phaffii (Pichia pastoris): Evaluation of up to 6 constructs with options for single- or multi-copy expression cassette integration. Includes promoter (methanol or methanol-free induction), signal peptide, and gene design variations. Aspergillus niger: Evaluation of up to 4 constructs with refined gene designs or signal peptides. Directed chromosomal multi-copy expression cassette integration (AMR-free). In all cases, the enzyme production will be validated via SDS-PAGE.

Plug & Produce (basic): Escherichia coli: Rapid plasmid-based expression (AMR or AMR-free). Bacillus subtilis: Chromosomal integration (AMR-free) with evaluation of up to 2 constructs (e.g. signal peptide or gene design variations). Komagataella phaffii (Pichia pastoris): Evaluation of up to 2 constructs using different promoters (methanol or methanol-free induction), signal peptides, or gene designs chromosomally integrated (AMR-free).

Plug & Produce (extensive): Bacillus subtilis: Chromosomal integration (AMR-free) with evaluation of up to 6 constructs with variations in signal peptides, codon optimization, or strain genotypes. Komagataella phaffii (Pichia pastoris): Evaluation of up to 6 constructs with options for single- or multi-copy expression cassette integration. Includes promoter (methanol or methanol-free induction), signal peptide, and gene design variations. Aspergillus niger: Evaluation of up to 4 constructs with refined gene designs or signal peptides. Directed chromosomal multi-copy expression cassette integration (AMR-free). In all cases, the enzyme production will be validated via SDS-PAGE.

If higher product yields are desired, bioprocesses can be specifically optimized for the product. Process development is carried out in 2 – 10 L scale, along with the associated DSP including chromatography if needed. A range of methods is applied, from DOE (Design of Experiments) to Process Intensification.

If higher product yields are desired, bioprocesses can be specifically optimized for the product. Process development is carried out in 2 – 10 L scale, along with the associated DSP including chromatography if needed. A range of methods is applied, from DOE (Design of Experiments) to Process Intensification.

Not every project starts from discovery - and it doesn’t need to. Whether your enzyme was developed in-house or elsewhere, our scale up and fermentation team can take it from proven concept to full-scale production. With extensive expertise in process transfer, optimisation, and downstream processing, we ensure reliable & high-yield manufacture.

Not every project starts from discovery - and it doesn’t need to. Whether your enzyme was developed in-house or elsewhere, our scale up and fermentation team can take it from proven concept to full-scale production. With extensive expertise in process transfer, optimisation, and downstream processing, we ensure reliable & high-yield manufacture.

Enzyme Discovery Services

If an analytical method is already available, we transfer it in-house to test enzyme activities and characterize relevant enzyme properties. For method transfer, you can rely on decades of experience in enzyme assay development, validation, and optimization. Our facilities include instruments for both small-volume, high throughput assays (plate readers) as well as for detailed analyses using HPLC and GC.

Method development:

If no analytical method exists, we develop one and then perform enzyme characterization for reliable results. We can leverage a collection of established methods and adapt them for each specific enzyme, from fluorescence-labeled substrates for high-throughput screenings to in-depth characterization via HPLC.

If an analytical method is already available, we transfer it in-house to test enzyme activities and characterize relevant enzyme properties. For method transfer, you can rely on decades of experience in enzyme assay development, validation, and optimization. Our facilities include instruments for both small-volume, high throughput assays (plate readers) as well as for detailed analyses using HPLC and GC.

Method development:

If no analytical method exists, we develop one and then perform enzyme characterization for reliable results. We can leverage a collection of established methods and adapt them for each specific enzyme, from fluorescence-labeled substrates for high-throughput screenings to in-depth characterization via HPLC.

Enzyme Engineering for Customised Biocatalysts that work in Application

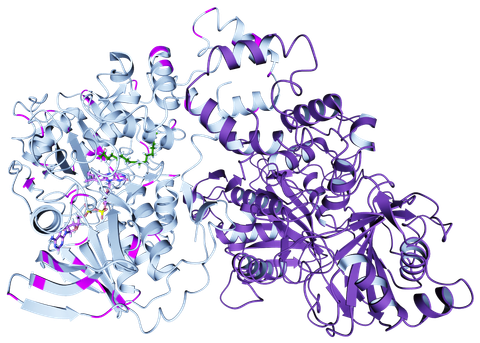

For rational enzyme engineering, we leverage our sequence- and structural bioinformatics pipelines. Enzyme libraries will be generated and improved enzymes are identified through multiparameter screenings (library size 100 - 1,000 variants). For each improved enzyme, the mutation details and corresponding performance improvements are documented.

Each subsequent round of enzyme engineering is based on the data from the previous round and makes use of this information. In addition to a renewed bioinformatic evaluation, combinatorial mutagenesis of beneficial mutations is also performed.

This process can be repeated as many times as needed until the target is achieved – a biocatalyst that fits the application perfectly.

For rational enzyme engineering, we leverage our sequence- and structural bioinformatics pipelines. Enzyme libraries will be generated and improved enzymes are identified through multiparameter screenings (library size 100 - 1,000 variants). For each improved enzyme, the mutation details and corresponding performance improvements are documented.

Each subsequent round of enzyme engineering is based on the data from the previous round and makes use of this information. In addition to a renewed bioinformatic evaluation, combinatorial mutagenesis of beneficial mutations is also performed.

This process can be repeated as many times as needed until the target is achieved – a biocatalyst that fits the application perfectly.

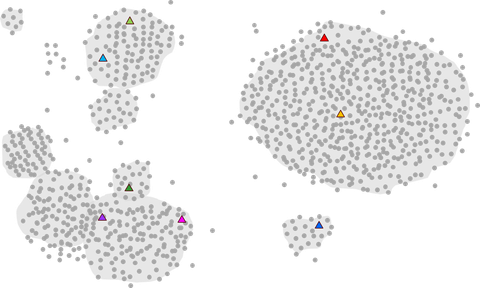

Before we start an enzyme engineering, we can scan nature’s diversity to find a better starting sequences that already largely exhibits the desired properties. During an enzyme engineering and the discovery of promising mutations, we can also analyse if any natural enzymes already carry those beneficial mutation. In this way we can enrich enzyme engineering with exciting biodiversity from MetXtra™ and expand the accessible sequence space.

Before we start an enzyme engineering, we can scan nature’s diversity to find a better starting sequences that already largely exhibits the desired properties. During an enzyme engineering and the discovery of promising mutations, we can also analyse if any natural enzymes already carry those beneficial mutation. In this way we can enrich enzyme engineering with exciting biodiversity from MetXtra™ and expand the accessible sequence space.

Get Started Today

Whether you’re starting with discovery, exploring diversity, or scaling up for commercialisation, our team is here to help. With flexible work packages, proven platforms, and deep scientific expertise, we’ll tailor the right solution for your project.